Luxury marble sheets have become a highly desired element in modern interior design. The product provides premium marble appearance through simple installation and minimal upkeep and adaptable usage. Luxury marble wall panels serve as the premium solution for enhancing interior spaces through their high-end appearance without requiring real stone installation complexities or expenses.

Before starting your installation work you need to understand four critical aspects regarding material selection and surface preparation and tool requirements and maintenance procedures. This guide provides complete information about what you need to know before starting your luxury marble sheet wall installation project.

Why Choose Luxury Marble Sheets?

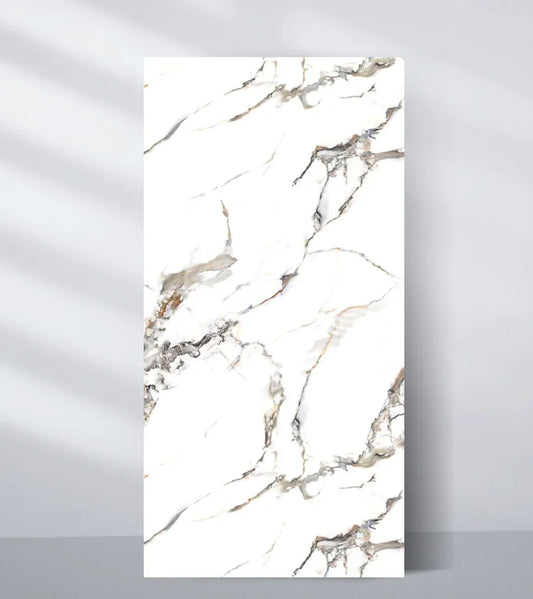

The product line includes luxury marble sheets which function as thin wall panels that duplicate the appearance of real marble through their authentic veining patterns and deep colors and natural surface texture. The production materials of PVC and acrylic and composite resins create wall panels that offer better workability and lower expenses than traditional stone slabs.

The product provides users with multiple vital benefits.

- The product features light weight construction which makes installation simple while offering resistance to moisture and mold growth suitable for bathroom and kitchen and basement areas.

- The product features authentic marble appearance in multiple color options including Carrara white and Calacatta gold and Nero Marquina black and additional designs.

- The product features excellent appearance with its realistic marble design.

- The product requires no maintenance because it needs no sealing or polishing.

1. Evaluate the Installation Area

The selection process for marble sheets requires you to determine their installation locations. Waterproof materials need installation in areas that stay wet for long periods including shower enclosures and backsplashes. The installation of heat-resistant panels needs to occur in areas which directly face heat exposure such as stove locations.

The standard locations for installing these materials include the following areas.

- Bathrooms (shower walls, vanity backdrops)

- Living rooms

- Kitchens

- Commercial lobbies

- Home offices and lounges

The installation area needs inspection for any signs of unevenness and dampness and paint deterioration. A successful installation depends on having a flat surface that remains dry throughout the process.

2. Choose the Right Type of Luxury Marble Sheet

The market offers multiple choices which depend on your preference between design elements and functional requirements. The market leading types of marble sheets include:

- PVC Marble Sheets provide lightweight construction with water resistance which makes them suitable for bathroom and kitchen areas.

- Acrylic Marble Panels offer better flexibility than other options while producing high-gloss finishes.

- The composite marble sheet offers improved durability and weight performance for commercial buildings and luxury residential areas.

A wall decor specialist will help you determine the suitable sheet type by connecting its specifications to your specific requirements.

3. Measure and Plan Layout Carefully

The process of working with luxury wall panels requires exact measurements because any small error will result in unsightly joints and unnecessary material waste and pattern misalignment. The process requires completion of these steps before beginning any cutting or adhesive application.

- Measure all wall dimensions before beginning work

- Determine the exact positions of all seams

- The marble veining pattern needs to be placed for achieving a natural appearance.

- Moisture-sensitive areas require expansion gaps to be included in the design.

4. Gather the Right Tools and Materials

The installation process for marble wall panels needs minimal equipment because they differ from heavy stone slabs which require cranes and professional masonry tools. The installation process requires these specific pieces of equipment.

- A utility knife or fine-tooth saw serves as the primary tool for cutting purposes.

- The installation process needs both measuring tape and a level to achieve accurate results.

- The recommended adhesive for this installation is either silicone-based or panel glue which the manufacturer should specify.

- The caulk gun serves as a tool for applying caulk.

- The installation process requires both panel spacers and temporary supports for support.

- The installation process requires cleaning cloths for maintenance.

The installation process requires waterproof adhesive for edge sealing through the application of mold-resistant silicone caulk.

5. Surface Preparation Is Crucial

The wall needs complete cleaning before starting the installation process. The surface needs to be free from all types of dust and oil and paint residue and mold growth. The surface requires wall putty application or skim coating to achieve flatness because it displays unevenness or damage. The process of waterproofing surfaces in wet areas provides additional benefits to the installation.

The surface needs to be:

- Completely dry

- Completely flat with no roughness

- The surface contains no loose elements.

- Your adhesive brand might need surface priming before application

The installation process will produce weak panel bonds and visible panel warping when you fail to perform this essential step.

6. Dry Fit Before Final Placement

The panels need to find their permanent position before adhesive application because this step allows you to check their proper alignment and visual appearance. The process requires special attention to marble patterns which extend between different sheets.

The dry fit process enables you to:

- Verify all dimensions

- Observe how the veining patterns will appear in the finished installation

- Identify the exact wall positions for installation

- Perform all required work to modify electrical outlets and fixtures.

The dry fitting process serves two main purposes which include achieving book-matched designs and maintaining continuous patterns between different walls.

|

|

7. Apply the Panels with Precision

The installation process requires you to apply adhesive in vertical stripes or zigzag patterns to the back of the panel before beginning. You should use force to push the panel against the wall during the installation process.

The following steps will help you achieve perfect results during the application process:

- Start your work with the bottom section when dealing with big panels

- Check the straightness of each panel by using a spirit level during installation

- Users need to remove all excess adhesive from the surface immediately following the application process.

- The adhesive needs to dry according to the product instructions which typically takes 24 hours.

- The installation of trims at corners and edges will create a professional finish when you match them.

8. Finishing Touches: Trims, Sealants, and Care

The outer corners and baseboard intersections and window areas need to have matching trims or aluminum edging. The edges of all areas require waterproof silicone sealing especially in shower areas and sink locations.

The following instructions guide you through installation maintenance procedures after finishing the setup process.

- A soft damp cloth should be used to perform regular surface cleaning.

- Soft cleaning products should be used instead of abrasive scrubbers and scouring pads for cleaning purposes.

- The removal of stubborn stains from PVC surfaces requires the use of mild soap or PVC cleaner which is specifically made for PVC materials.

- The panels need backing material support before you can start using drilling or screwing tools.

Luxury marble sheets require minimal upkeep because proper care methods will help them maintain their perfect condition from start to finish.

9. Professional vs DIY Installation

Homeowners who possess DIY abilities can perform their own installations but they need to seek professional assistance when working on extensive projects or areas that experience water damage. A professional installer will provide the following benefits to your installation:

- The installer will correctly place all panels during installation.

- The installer will create waterproof seals for all areas which face water exposure.

- The installation process requires both corner trim and joint connection for achieving a clean finish.

- The system requires additional structural support through the installer whenever such needs arise.

Begin with a small accent wall project before you move on to install DIY projects on complete bathroom walls.

Final Thoughts: Your Dream Wall, Upgraded

Luxury marble sheets function as an excellent contemporary wall solution because they provide both beauty and durability and simple installation process. The panels from these sheets create both stylish and functional spaces which make them suitable for living room walls and bathroom transformations into spa-like areas.

The first step of installation requires you to develop a complete plan and select suitable materials and surface treatment techniques. Your marble-inspired wall panel installation will create timeless interior spaces that exude sophistication when you execute the process correctly. Wall Decor offers premium luxury marble sheets for interior transformation through their collection.